Manufacturing executives are facing mounting pressure to digitize their sales operations, as B2B buyers increasingly demand seamless online purchasing experiences. According to Digital Commerce 360, B2B eCommerce sales in the U.S. reached $2.64 trillion in 2024, representing a 16% year-over-year growth. The Wunderman Thompson B2B Future Shopper Report reveals that 67% of B2B buyers now start their purchase journey online, and 68% plan to increase their use of digital shopping channels, a shift that’s fundamentally reshaping the B2B eCommerce landscape.

Yet implementing eCommerce for manufacturing companies remains challenging for manufacturers dealing with complex product configurations, negotiated pricing structures, and deeply entrenched legacy systems. This guide offers a comprehensive roadmap for launching or optimizing eCommerce capabilities that address industry-specific challenges.

eCommerce for Manufacturing Companies: Challenges and Why Traditional Platforms Fall Short

Manufacturing companies face unique requirements that standard B2C eCommerce platforms cannot address. These challenges stem from complex product relationships, multi-tiered pricing structures, and integration demands with legacy enterprise systems.

Research indicates that 64% of B2B buyers are likely to switch vendors if competitors offer better digital features, such as personalized pricing and real-time inventory visibility. For manufacturers, inadequate digital experiences directly impact customer retention and competitive positioning. Successful B2B eCommerce solutions for manufacturers address these challenges through specialized features and deep system integration.

Unique Manufacturing Requirements

| Challenge Area | Traditional B2C Limitation | Manufacturing Need | Business Impact |

|---|---|---|---|

| Product Data | Simple SKU management | Technical specs, CAD files, certifications, compatibility data | Incomplete product info costs sales |

| Pricing Structure | Fixed list pricing | Contract-based, tiered, volume discounts, customer-specific rates | Manual pricing creates errors and delays |

| Order Processing | Single-item checkout | Bulk orders, recurring orders, quote requests, approval workflows | Complex orders require sales rep intervention |

| Inventory Management | Basic stock tracking | Real-time across warehouses, custom lead times, backorder handling | Inaccurate inventory damages customer trust |

| Customer Accounts | Individual shoppers | Multi-level buyer hierarchies, purchasing managers, approval chains | B2C portals frustrate B2B buyers |

| System Integration | Standalone platform | Deep ERP, PIM, CRM, accounting connections with bidirectional flow | Data silos require double entry |

The manufacturing buying process involves multiple stakeholders, extended sales cycles, and technical evaluation. A power tool distributor may manage thousands of SKUs with cross-references, whereas an industrial equipment manufacturer requires multi-component systems that include technical drawings and compliance documentation.

ERP Integration Essentials: The Foundation of Manufacturing eCommerce

ERP systems store the authoritative data that eCommerce for Manufacturing companies require: real-time inventory levels, contract pricing, customer credit limits, order history, and fulfillment status. Without bidirectional integration through proven ERP integration services, your eCommerce platform becomes a disconnected storefront that creates more work than value.

Critical ERP Integration Points

Order Management Flow: When customers place orders online, data must flow directly into your ERP for fulfillment processing. Automated order transfer ensures orders route correctly to warehouses, trigger production schedules, and update financial records without human intervention.

Inventory Synchronization: Real-time inventory visibility prevents overselling and sets accurate delivery expectations. Manufacturing involves multiple warehouses, custom lead times for made-to-order items, and complex availability scenarios. Your eCommerce platform should display actual availability and estimated ship dates pulled directly from ERP inventory data.

Manufacturers that integrate their ERP systems with eCommerce platforms reduce order processing times by up to 30%. For Adobe Commerce users, specialized Magento ERP integration solutions can accelerate this transformation through pre-built connectors and proven integration patterns. This comes from eliminating manual data entry, reducing errors, and enabling automatic fulfillment routing.

Pricing and Customer Data: B2B pricing is influenced by contract negotiations, volume commitments, and the strength of customer relationships. Your ERP maintains these pricing agreements, and eCommerce integration ensures buyers see their actual prices automatically. Customer credit terms, payment options, and purchasing limits also flow from ERP to eCommerce.

Integration Architecture Options

| Integration Type | Best For | Pros | Cons |

|---|---|---|---|

| Native Platform Integration | Standard ERP systems (SAP, NetSuite, Dynamics) | Pre-built connectors, lower cost, faster implementation | Limited customization options |

| Middleware/iPaaS | Complex integrations, multiple systems | Flexible data transformation, supports many systems | Additional platform costs, more complexity |

| Custom API Integration | Unique requirements, legacy systems | Complete control, tailored workflows | Higher development cost, ongoing maintenance |

| Batch File Transfer | Low transaction volumes, budget constraints | Simple implementation, low cost | Delays in data updates, limited functionality |

Product Data Management: Organizing Complex Manufacturing Catalogs

Manufacturing product data extends beyond basic descriptions and images. Technical specifications, compliance certifications, CAD files, installation guides, material safety data sheets, and compatibility matrices all influence buying decisions.

Why PIM Systems Matter for Manufacturers

PIM centralizes all product information in one system of record. Marketing descriptions, technical specifications, digital assets, and channel-specific content connect to master product records. Updates propagate automatically to eCommerce, print catalogs, distributor portals, and marketplace listings.

Without PIM, product data is often stored in spreadsheets, ERP systems, and individual computers. Updates require manual changes across multiple systems. Errors multiply, and marketing and engineering maintain conflicting information.

Manufacturing PIM Capabilities: PIM systems are designed to support complex product relationships and technical data requirements within manufacturing. They manage bill of materials relationships, product variants with different specifications, accessory and compatibility rules, and multi-language content for global markets.

Product Data Requirements by Industry

| Manufacturing Type | Critical Data Elements | Common File Formats | Update Frequency |

|---|---|---|---|

| Industrial Equipment | Technical specs, CAD files, capacity ratings, power requirements | DWG, PDF, STEP, IGES | Quarterly |

| Electronics Components | Electrical specifications, compatibility lists, datasheets, RoHS | PDF, CSV, XML, technical diagrams | Monthly |

| Automotive Parts | OEM part numbers, vehicle compatibility, installation guides | PDF, ACES/PIES data, images | Weekly |

| Building Materials | Dimensions, materials, certifications, installation specs | PDF, technical drawings, CAD files | Quarterly |

B2B Features Manufacturing Companies Need

eCommerce for manufacturing companies requires capabilities beyond consumer shopping carts. Business buyers expect account-specific experiences, purchasing tools for complex orders, and workflows that integrate with their procurement systems. Understanding essential B2B eCommerce features helps manufacturers select platforms that support these requirements.

Custom Pricing and Tiered Discounts

B2B pricing structures reflect negotiated contracts, volume commitments, and customer relationships. Manufacturing eCommerce platforms must display customer-specific pricing automatically when buyers log in.

Pricing Model Options:

- Contract-based pricing with negotiated rates per SKU

- Volume-based discounts are calculated automatically by order quantity

- Tiered customer groups with different price levels

- Time-based promotions for specific customer segments

- Cost-plus pricing for custom or engineered products

Byrne Electrical Case Study: When Byrne Electrical Specialists implemented their B2B eCommerce platform with Atwix, they needed seamless ERP integration to display real-time, customer-specific pricing. The solution eliminated the need for manual quote generation for standard orders, freeing sales teams to focus on more complex projects. The implementation was completed in just eight weeks during the pandemic, resulting in a 35% improvement in order accuracy.

Bulk Ordering and Quick Order Tools

Business buyers rarely purchase single items. Quick order forms accept SKU lists via CSV upload or manual entry. Buyers paste part numbers from procurement systems, upload previous order files, or manually enter familiar SKUs. The system validates inventory and displays prices instantly.

Saved order lists store frequently purchased item combinations. Maintenance teams can easily reorder standard supplies with one click, and production buyers can recall the bill of materials for repeat projects.

Request for Quote Functionality

Complex or custom orders require a quote to be generated before purchase. Manufacturing eCommerce platforms offer RFQ workflows that capture requirements, route requests to the appropriate sales representatives, and convert approved quotes into orders.

RFQ features include:

- Custom quantity requests beyond standard inventory

- Product configuration tools for customizable items

- File attachment for drawings or specifications

- Delivery date negotiations with lead time visibility

- Approval workflows within customer organizations

Account Management and User Permissions

Manufacturing customers often have complex purchasing organizations. Procurement managers set policies, engineers specify products, purchasing agents place orders, and finance teams review spending.

B2B eCommerce accommodates these roles through account hierarchies and permission controls. Parent accounts establish purchasing policies for subsidiary locations. User roles determine who can browse, request quotes, place orders, or access invoices.

User Roles and Permissions

| User Role | Browse Products | Request Quotes | Place Orders | View Pricing | Approve Orders | |

|---|---|---|---|---|---|---|

| Viewer | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ |

| Requester | ✔ | ✔ | ✘ | ✔ | ✘ | ✘ |

| Buyer | ✔ | ✔ | ✔ | ✔ | ✘ | ✔ |

| Approver | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Administrator | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Technology Stack Recommendations for Manufacturing eCommerce

Selecting the right platform for eCommerce for manufacturing companies determines what capabilities your digital channel can support. Manufacturing requirements eliminate many popular consumer-focused platforms. Therefore, your evaluation should focus on the platform’s depth of B2B features, integration capabilities, and scalability for complex catalogs.

Platform Comparison for Manufacturing

| Platform | Best For | Key Strengths | Manufacturing Fit | |

|---|---|---|---|---|

| Adobe Commerce (Magento) | Mid to large manufacturers | Deep B2B features, unlimited customization, robust API | Excellent | 6-12 months |

| BigCommerce B2B Edition | Growing manufacturers | Built-in B2B tools, SaaS reliability, lower TCO | Good | 3-6 months |

| Shopify Plus | Hybrid B2B/B2C | Fast deployment, easy management, strong design | Limited for complex B2B | 2-4 months |

| Shopware | Mid-sized to enterprise manufacturers | API-first architecture, modular B2B suite, flexible pricing, strong ERP integration | Very good | 4-8 months |

| Salesforce Commerce Cloud | Large enterprises | Tight CRM integration, AI capabilities, global scale | Good | 9-18 months |

Adobe Commerce Advantages: Adobe Commerce (formerly Magento) dominates manufacturing eCommerce with support for unlimited product attributes, complex pricing rules, sophisticated account hierarchies, and deep ERP integration out of the box. Advanced catalog management handles configurable products with dependent options. B2B-specific features include company accounts, quote management, and requisition lists, all without the need for third-party extensions.

Atwix specializes in Adobe Commerce implementations for manufacturers, bringing over 300 certifications and recognition as the #1 contributor to Adobe Commerce since 2018. Our comprehensive B2B eCommerce services help manufacturers navigate platform selection, implementation, and ongoing optimization.

Shopware Advantages for Manufacturing: Shopware offers a modular approach with its B2B Suite, making it an ideal solution for manufacturers that require flexibility without the complexity of Adobe Commerce. The platform’s API-first architecture ensures seamless Shopware integrations with ERP, PIM, and CRM systems.

Shopware’s key manufacturing features include:

- Advanced B2B account management with parent-child hierarchies

- Customer-specific pricing and catalogs

- Bulk ordering and quick reorder functionality

- Multi-level approval workflows

- Quote management system

- Headless commerce capabilities for custom front-ends

Atwix holds Shopware certifications and brings expertise in implementing Shopware B2B solutions for manufacturers requiring scalable, modern eCommerce platforms with strong B2B capabilities.

Essential Technology Components Beyond the Platform

Manufacturing eCommerce requires the following supporting technologies to work together seamlessly:

Product Information Management (PIM): Centralized product data management feeding eCommerce, print, and distribution channels. Leading solutions include Akeneo, inRiver, and Salsify.

Enterprise Resource Planning (ERP): Core business system managing inventory, orders, accounting, and customer data. Common manufacturing ERPs include SAP, NetSuite, Microsoft Dynamics, Epicor, and Infor.

Configure Price Quote (CPQ): Automates pricing and quote generation for complex, configurable products. Tools like Salesforce CPQ or Oracle CPQ integrate with eCommerce platforms.

Customer Relationship Management (CRM): Tracks customer interactions, sales pipeline, and account history. Salesforce, HubSpot, and Dynamics CRM connect to eCommerce for unified customer views.

Order Management System (OMS): Orchestrates order fulfillment across warehouses, drop shippers, and third-party logistics providers.

Integration between these systems creates seamless data flow:

- Orders from eCommerce trigger ERP fulfillment

- Product updates in PIM propagate to eCommerce

- Customer interactions in CRM inform personalized eCommerce experiences

These benefits of integrated eCommerce compound over time as data quality improves and automation reduces manual intervention.

Implementation Roadmap: From Planning to Launch

Manufacturing eCommerce projects succeed through phased implementation that delivers value incrementally. Breaking the project into manageable phases allows for earlier ROI and course corrections based on user feedback.

Implementation Timeline and Resource Estimates

| Phase | Duration | Key Activities | Internal Resources | External Partner Hours |

|---|---|---|---|---|

| Foundation & Strategy | 6-8 weeks | Requirements, platform selection, strategy | 20-30 hrs/stakeholder | 120-160 hours |

| Build & Integrate | 12-16 weeks | Platform build, ERP integration, custom features, product data migration | 30-50 hrs/week | 760-1160 hours |

| Testing & Training | 4-6 weeks | UAT, performance testing, training | 20-30 hrs/week | 120-200 hours |

| Launch & Optimization | 2-4 weeks | Monitoring issue resolution, optimization | 15-25 hrs/week | 80-120 hours |

The total project timeline typically ranges from 6 to 12 months, depending on catalog size, integration complexity, and custom feature requirements.

Phase 1: Foundation and Strategy (Weeks 1-8)

Discovery and Requirements: Document current state processes, pain points, and desired outcomes. Interview sales teams, customer service, operations, and key customers. Map existing systems and data flows.

Define success metrics, including order volume targets, customer adoption rates, cost reductions, or sales growth objectives. Establish baseline measurements for comparison after launch.

Platform and Partner Selection: Evaluate eCommerce platforms against requirements. Request demonstrations focused on manufacturing use cases, including product configuration, complex pricing, and ERP integration. Select technology partners, including platform implementation specialists and ERP integration experts.

Information Architecture and Design: Create a site structure that supports how buyers actually search and navigate. Organize products by application, industry, or technical specifications. Design account management interfaces, ordering workflows, and self-service tools.

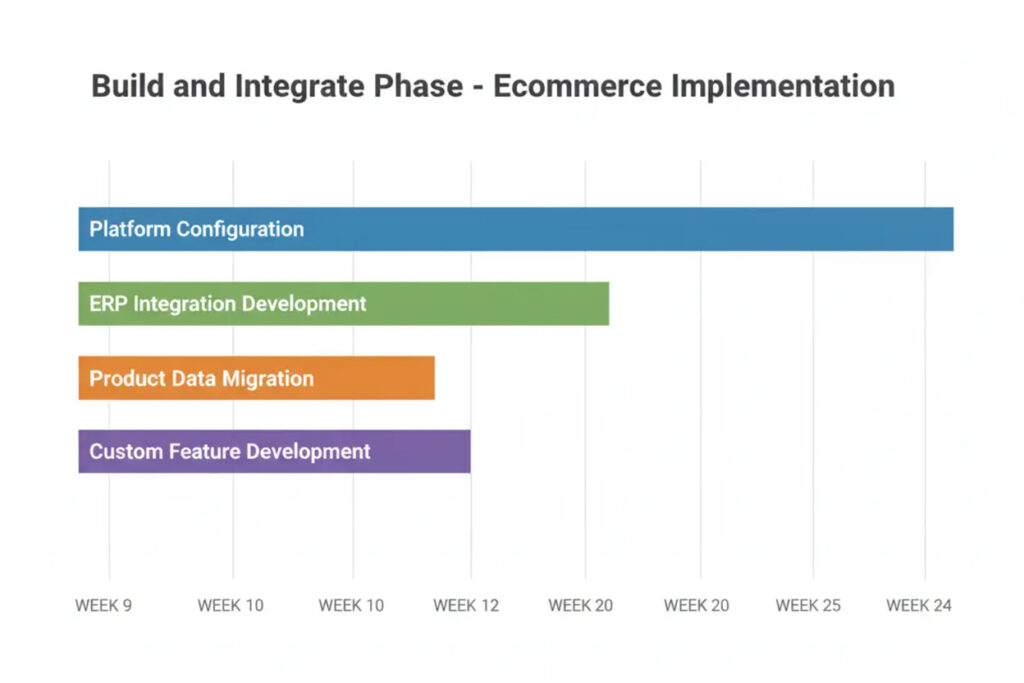

Phase 2: Build and Integrate (Weeks 9-24)

Platform Configuration: Set up the base eCommerce platform, theme, and core features. Configure product catalog structure, customer account hierarchies, and pricing rules. Establish security protocols and performance foundations.

ERP Integration Development: Establish connections between eCommerce and ERP systems for seamless order, inventory, customer, and pricing management. Develop data transformation logic to bridge system differences. Implement error handling and monitoring to address integration failures.

Product Data Migration: Clean, standardize, and import product information to ensure accuracy and consistency. Enrich technical specifications, add images and documents, and validate data accuracy. This often takes longer than expected because product data lives in multiple systems with inconsistent formats.

Custom Feature Development: Build manufacturing-specific capabilities not available by default. Common custom features include product configurators, technical specification filters, custom quote workflows, and specialized reporting.

Phase 3: Testing and Training (Weeks 25-30)

User Acceptance Testing: Engage internal teams and select customers in structured testing. Validate ordering workflows, pricing accuracy, account management, and integration behavior. Test with realistic scenarios, including bulk orders, custom pricing, product configuration, and quote requests.

Team Training: Train customer service representatives on managing online accounts and troubleshooting issues. Educate sales teams on positioning eCommerce as a complement to their relationships. Prepare content and resources for customer onboarding, including how-to guides and video tutorials.

Performance Optimization: Load test the platform to verify it handles expected traffic and order volumes. Optimize page speed, especially for large catalogs and product configurators. Tune integration performance to maintain real-time responsiveness.

Phase 4: Launch and Optimization (Week 31 and Beyond)

Soft Launch: Begin with a limited customer group or product segment. Monitor closely for issues, gather feedback, and make adjustments. This controlled launch reduces risk and allows for fixing problems before full rollout.

Full Launch: Open to all customers with coordinated announcement. Communicate benefits, provide training resources, and offer incentives for early adoption. Make support easily accessible as customers become familiar with the new system.

Continuous Improvement: Analyze usage patterns to identify areas of friction. Implement improvements based on data, including enhanced search and filtering, streamlined checkout, additional self-service tools, and expanded product information.

Choose the Right Solution for Your Manufacturing Business

Manufacturing eCommerce success requires more than an online catalog; you need platforms built for B2B complexity, integrations that connect your existing systems, and implementation partners who understand the intricacies of manufacturing operations.

Manufacturers that thrive with eCommerce for manufacturing companies start with a clear strategy aligned to business objectives, invest in proper technical foundations, including robust ERP integration, and commit to ongoing optimization. They view eCommerce as a growth channel that complements sales teams rather than replacing human relationships.

Research shows that 71% of B2B buyers are Millennials and Gen Z, who expect seamless online experiences. Manufacturers who delay digital transformation risk becoming irrelevant in an increasingly digital marketplace, where competitors are rapidly advancing their capabilities.

Atwix has helped manufacturing companies across industries transform their digital commerce capabilities. Our expertise with Adobe Commerce, complex ERP integrations, and manufacturing-specific requirements accelerates your path to market while avoiding costly mistakes. With over 300 certifications and recognition as the #1 contributor to Adobe Commerce since 2018, we bring proven methodologies and deep technical expertise to every manufacturing implementation.

Choose The Right Solution for Your Manufacturing Business – Contact Atwix Today